Chinese name: Nano zinc oxide

Alias: Nanozinc white

Molecular formula: ZnO

Molecular weight: 81.39

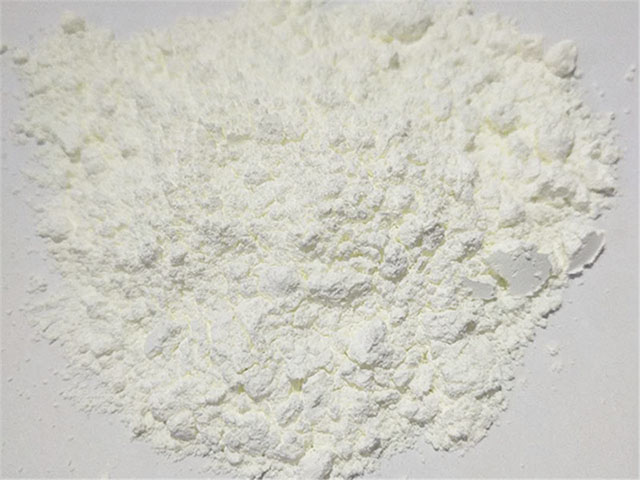

Appearance: white or yellowish fine powder

Details:

Our company has developed and used the wet ultra-fine zinc oxide process. It uses defective zinc oxide, washed and leached, and removes copper, lead, iron, and manganese. Deep static, neutralization, drying, calcination, the production of ultra-fine active zinc oxide, Nano zinc oxide, active zinc oxide products.

Compared with the existing zinc oxide production processes, the advantages of the wet ultra-fine zinc oxide new process:

1, high product activity. The production principle of zinc oxide is different, and the crystal type of the product is also different. Therefore, the chemical activity is very different. The ultra-fine zinc oxide produced by the wet process has a structure with fine grain size, large specific surface area, and porous crystal shape. Therefore, it has the characteristics of high chemical activity.

2, the product purity is high. Due to the application of various purification measures in the production of wet method, the impurity metal content is reduced to extremely low.

3, a variety of products. Indirect method is limited by the process, only one product-indirect zinc oxide. The wet process can produce zinc oxide and zinc salt products with different properties by fine-tuning the process. To meet the different needs of users. Adapt to the broad needs of the market.

4, raw materials from a wide range of sources. Wet process raw materials have wide adaptability. Zinc calcined sand, low zinc oxide, zinc ash, diamond zinc ore, etc. can all be used as raw materials for wet process production. Now that mineral resources are becoming increasingly scarce, this is a great advantage.

5, in the production process to achieve the control of impurities, according to the needs of different users to produce. The content of metals such as lead and cadmium can be controlled below 5 ppm.

In addition, by adjusting certain process parameters and process processes, we can produce 99.7 % of Gaochun nanometer zinc oxide and active zinc oxide. This is a rare breakthrough in China and can replace part of Gaochun indirect zinc oxide.

Customer message: Dear customers, if you have a special product specifications, we can provide technical services for the products you need to carry out process modification, production of your special products, please leave a message to inform.

Nano zinc oxide color characteristics:

Nano-active zinc oxide has a variety of production methods, and the differences in each production method and the process of each production method make the color of the product different, that is, the degree of yellowness is different.

First, the origin of material color.

The color of a substance is the result of its reflection. White light is a mixture of light from various colors in a certain proportion. If a substance appears yellow in a white light environment(such as nano zinc oxide), it is because the object absorbs some or all of the blue light. The color of a substance is due to its selective absorption of light of different wavelengths.

Different colors of light have different wavelengths, and different substances absorb different wavelengths of color light. Matter can only selectively absorb radiation light that is equivalent to the sum of the changes in the kinetic energy of the molecule, the changes in the rotational energy, and the changes in the energy of the electron movement. In other words, even if it is the same substance, if it can be in different energy levels, its color will be different. For example, zinc oxide, whether in the ordinary form or in the nanometer form, is very yellow at high temperatures and lighter when the temperature decreases. The reason is that at different temperatures, the molecular energy of zinc oxide and the transition energy of electron energy are different, so the absorption of various colors of light is different.

Second, the structural difference between coarse particles of zinc oxide and nanometer zinc oxide, and the resulting intramolecular energy differences.

The direct or indirect method of coarse particles is the ion crystal. In general, zinc atoms and oxygen atoms exist in the form of Ionic bonds. Due to its thick particles, the number of oxygen atoms and zinc atoms in each particle is quite large, and the number of the two atoms is the same(according to the molecular formula ZnO, it is 1:1). However, for nanometer zinc oxide, the particles are quite fine, which greatly increases the number of unbonded atoms on the surface of the particles. In other words, nanometer zinc oxide can no longer be seen as an ideal crystal with an infinite number of ideal crystal surfaces. On its surface, there will be disordered intercrystalline structures and crystal defects. The presence of these atoms on the surface that are different from the central part makes it have a strong ability to react with other substances, which is what we usually call activity.

Studies have shown that there are at least three states of oxygen in nano zinc oxide: lattice oxygen(located inside the particles), surface adsorbed oxygen and hydroxyl oxygen(-OH), and that the amount of zinc in the particles is greater than the amount of oxygen., It's not a 1:1 situation. This is completely different from ordinary zinc oxide. There are oxygen gaps on the surface of Nano zinc oxide, and there are many suspended bonds that are easy to react with other atoms. This is also the basic principle of the application of Nano zinc oxide as an active agent in rubber and catalysts.

Due to the above differences between Nano zinc oxide and ordinary zinc oxide. The transition energy levels of molecular energy and electron energy in the particles are different, so the color is also different. Normal zinc oxide is white, while nanometer zinc oxide is yellowish.

Third, the color of nanometer zinc oxide changes with time and environmental humidity.

For Nano zinc oxide, due to the presence of adsorbed oxygen and hydroxyl oxygen on the surface of its particles, the amount of these two types of oxygen will change over time, such as the adsorption of water and the readsorption and stripping of oxygen in the air. The change in the number of these two types of oxygen will inevitably cause changes in the molecular and electronic energy levels in the particles, and the absorption of light is not the same. Therefore, the color of zinc oxide becomes lighter.

Fourth, the relationship between the color and purity of nanometer zinc oxide.

Pure nanometer zinc oxide, its color is pure yellowish, appears very bright color. When nanometer zinc oxide contains impurities such as iron, manganese, copper, and cadmium to a certain extent, the color of zinc oxide will have a soil color in the yellowish color, because iron, manganese, copper, cadmium, etc.. Oxides are colored substances, After mixing with each other, several colors are mixed and white is unearthed. The color change of Nano zinc oxide(or active zinc oxide, light zinc oxide) over time will be covered by soil color, making the color change appear to be minimal; When the impurities in the Nano zinc oxide are higher, the color will become deep, and it is impossible to observe the color changes over time.

As mentioned above, the color of a substance is caused by its selective absorption of external light. Therefore, when we compare the color of zinc oxide, we try to observe it in an outdoor bright place. The choice of different environments for comparison will result in different comparative results, which also reflects the interest of light reflection.

Another explanation for the color of nanometer zinc oxide.

Nano zinc oxide is obtained by calcination of alkali zinc carbonate. In this process, if basic zinc carbonate is not completely decomposed, the color of Nano zinc oxide will appear white because basic zinc carbonate is pure white. In addition, production in the South and North, or production in wet rainy and dry weather, will also affect color. Because nanometer zinc oxide reacts with wet air and carbon dioxide to form alkaline zinc carbonate, a reverse reaction of the calcination process occurs. The extent to which this change has an impact on product quality is still difficult to determine because basic zinc carbonate itself is also catalytic and suitable for use in the desulfurization agent and rubber industry; In the feed industry, basic zinc carbonate has the same function as zinc oxide. It is also a feed additive. At the same time, in the feed industry, our concern is mainly whether the content of heavy metals meets the standard requirements.

Mobile station

Copyright All Rights Reserved Jiangxi Fool Nanotechnology Co., Ltd.

Technical Support:

Contact: 13907064196 Tel: 0796-2620699 Address: Salt Industry City, XinGan County, Ji'an City, Jiangxi Province